About Us

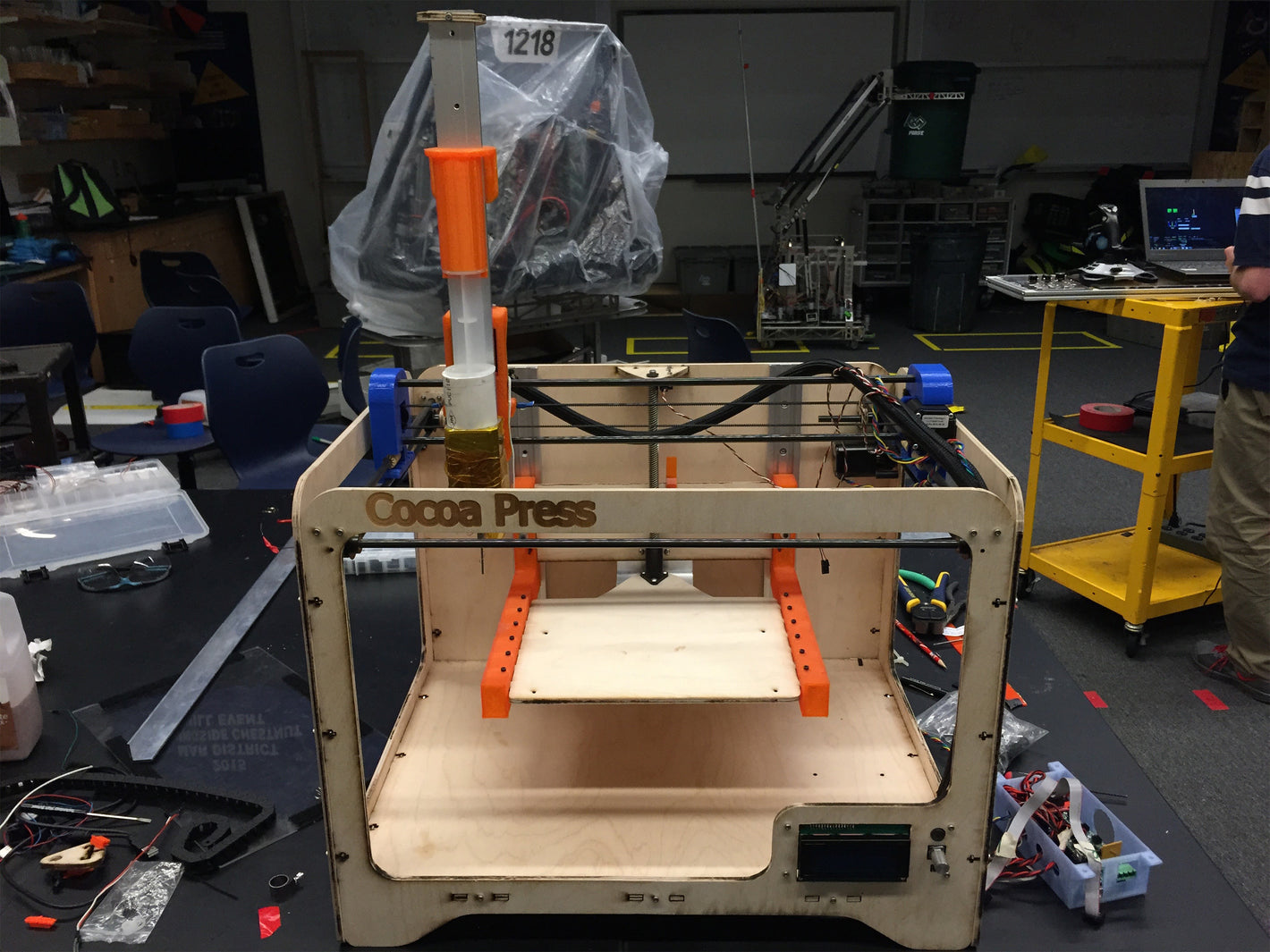

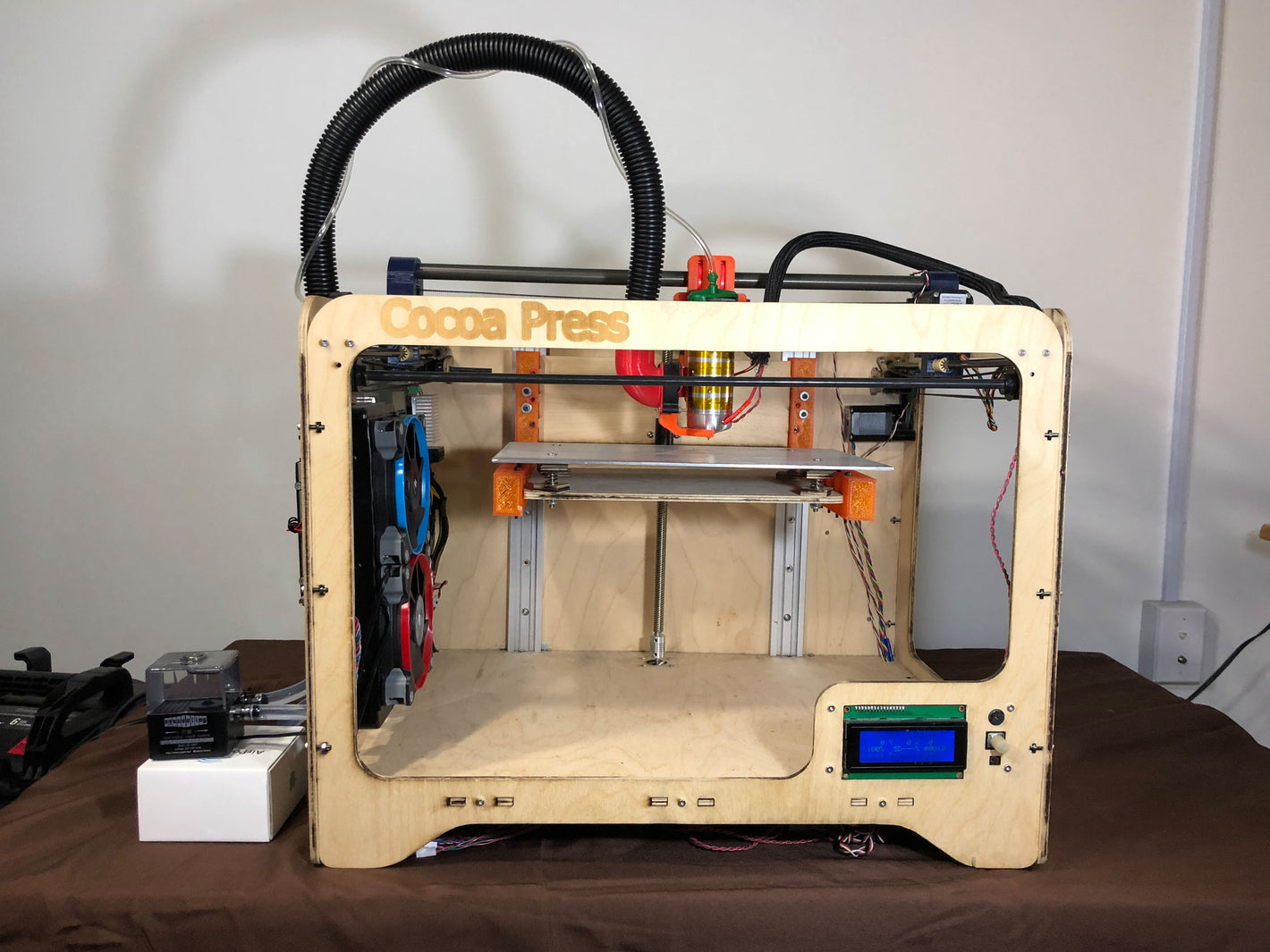

Cocoa Press is shaping the future of chocolate using 3D printing to enable personalized, on demand confections.

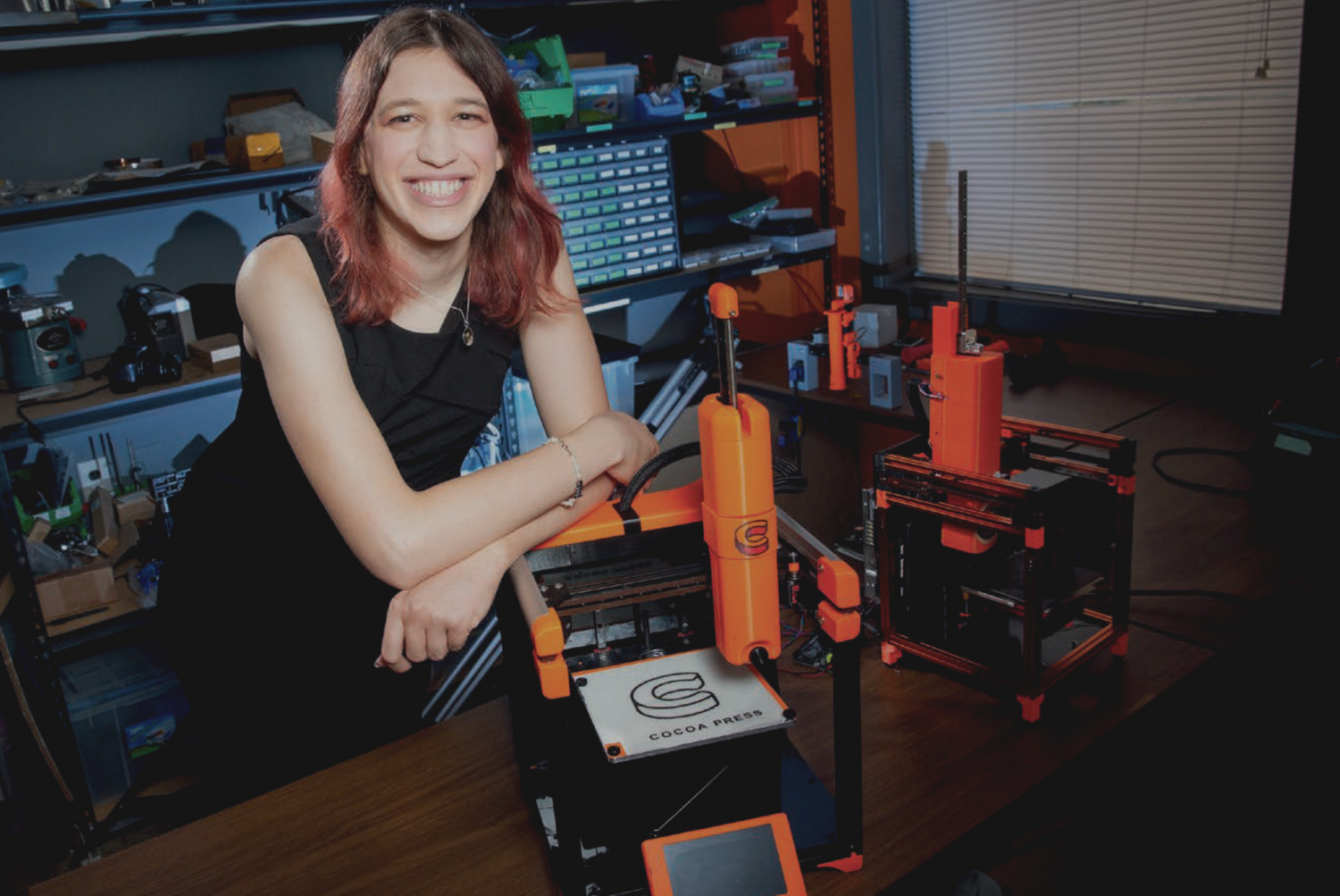

Ellie started working on Cocoa Press in 2014 during an intro to engineering class in high school. She graduated from Penn Engineering in 2019 and began working on Cocoa Press full time after 5 years of it being her hobby.

Ellie has also appeared on the Battlebots TV show as a part of team Mammoth and is passionate about the ways we can use 3D printing across industries. When not 3D printing she sings and enjoys weaving, woodworking and glassblowing while fighting for trans rights across the US.

Meet our Team

-

Ellie

Founder, CEO

-

Kim

Technical Support Engineer

-

River

Production Specialist

-

Maks (RCF)

Incredible Mechanical Design

-

Gregg

Assembly Manual

-

Marcio

Firmware Development

-

Emma

Customer Support

-

Ellis

Customer Support

-

LDO Team

Manufacturer